Unlocking the Prospective: Purchasing Long Lasting Mining Equipment Parts for Success

Unlocking the Prospective: Purchasing Long Lasting Mining Equipment Parts for Success

Blog Article

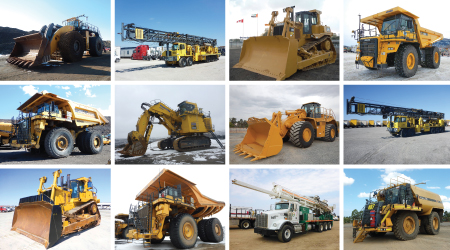

Unveiling Necessary Mining Tools Components for Optimum Operations

In the detailed world of mining procedures, the smooth functioning of equipment is paramount. Behind the scenes of every successful operation lies a thorough option of vital parts that play an essential duty in guaranteeing ideal efficiency. From drill little bits that sculpt via rock with accuracy to conveyor systems that simplify product transportation, each element is a gear in the equipment of productivity. As we dive into the midsts of mining tools basics, a closer take a look at the elaborate information and performances of these parts introduces a remarkable world where effectiveness and reliability are the foundations of success.

Value of Correct Drill Bits

Appropriate option and maintenance of drill little bits are fundamental for taking full advantage of mining efficiency and performance. Pierce little bits are vital components in the mining market, liable for the infiltration of the earth's surface area to remove useful minerals. The sort of drill little bit selected need to straighten with the specific geological problems of the mining site to make certain optimal efficiency. Elements such as firmness of the rock, piercing deepness, and wanted penetration rate must be considered when picking the ideal drill little bit.

Routine maintenance of drill little bits is similarly vital to make sure long life and efficiency. Damaged or boring drill bits can bring about reduced drilling rate, raised wear on drilling equipment, and eventually, lowered efficiency. Maintenance tasks may consist of sharpening, regrinding, or changing used components to keep the drill little bits in leading working condition.

Secret Elements in Conveyor Equipments

Efficient product transport in mining procedures greatly relies upon the functionality and integrity of crucial components in conveyor systems. One essential part is the conveyor belt itself, which lugs the products along the mining site. The high quality and sturdiness of the conveyor belt are important to stop breakdowns and make certain a smooth flow of products. One more essential element is the idler, which sustains the conveyor belt and assists maintain appropriate stress for reliable operation. Idlers are strategically put along the conveyor system to minimize friction and support the weight of the materials being carried - mining equipment parts.

Important Filters for Tools Upkeep

An essential aspect of making certain the durability and ideal performance of mining devices hinges on the careful selection and maintenance of essential filters. Filters play a critical function in guarding mining equipment from impurities that can trigger damage, resulting in costly repair services and downtime. Dirt, debris, and dust are pervasive in extracting atmospheres, making the correct filtration system important to devices longevity.

Filters in mining tools serve to trap particles that might infiltrate delicate components such as engines, hydraulics, and transmissions. On a regular basis replacing these filters according to maker suggestions is necessary to stop blocking and make certain effective operation. Disregarding filter upkeep can lead to reduced equipment life expectancy, decreased efficiency, and enhanced gas consumption.

Crucial Put On Components for Crushers

In the realm of mining tools upkeep, one important aspect that requires focus is the identification and replacement of essential wear components for crushers. Crushers play a fundamental duty in the ore handling and worldly decrease processes within mining procedures. A few of the vital wear parts that are necessary for the effective performance of crushers include the following:

** Crusher Liners **: These are vital in shielding the crusher covering from damage brought on by the material being squashed.

** Jaw Plates **: Established in jaw crushers, these parts are liable for squashing the material against a taken care of surface.

** Mantles and Concaves **: These parts are vital in gyratory crushers, where they assist in Recommended Reading squashing the material into a much more refined kind.

Regular inspection and substitute of these wear components are necessary to guarantee the crushers operate at their ideal effectiveness, decreasing downtime and making best use of efficiency in mining procedures. Appropriate maintenance of these wear parts can substantially influence the general efficiency and long life of the crushers, ultimately adding to the success of mining tasks.

Role of Hydraulic Cyndrical Tubes in Mining

Playing a crucial duty in contemporary mining operations, hydraulic cyndrical tubes are important elements that help with the efficient functioning of numerous heavy machinery. These hydraulic cyndrical tubes are critical for powering crucial mining devices such as excavators, excavators, drills, and loaders. Among the main functions of hydraulic cyndrical tubes in mining is to give the force needed to move hefty tons and products in tough terrains. The capability of hydraulic cylinders to generate enormous power in a regulated way makes them vital for jobs like training, pressing, drawing, and crushing within mining operations.

Hydraulic cylinders in mining devices are developed to withstand rough operating problems, including severe temperatures, high pressures, and heavy loads. Their toughness and dependability add to the overall performance and safety and security of mining operations. Proper upkeep and routine examination of hydraulic cylinders are important to guarantee optimal efficiency and protect against expensive breakdowns that can stop mining tasks. In significance, hydraulic YOURURL.com cyndrical tubes play a critical duty in enhancing the efficiency and efficiency of mining procedures worldwide.

Final Thought

To conclude, it is crucial for mining procedures to utilize proper drill little bits, crucial parts in conveyor systems, vital filters for tools maintenance, important wear parts for crushers, and hydraulic cylinders. These necessary mining tools parts play a considerable role in making best use of and guaranteeing optimal procedures performance in the mining industry. By buying top quality and reliable devices parts, mining companies can improve performance and lessen downtime, inevitably resulting in a more successful procedure.

In the elaborate globe of mining operations, the smooth functioning of equipment Discover More Here is critical. By spending in premium purification systems and sticking to a stringent maintenance schedule, mining operations can improve equipment dependability, reduce downtime, and inevitably maximize performance.

In the realm of mining devices upkeep, one essential element that requires attention is the identification and substitute of necessary wear components for crushers. These essential mining tools parts play a substantial duty in making best use of and guaranteeing ideal operations performance in the mining sector. By investing in dependable and premium tools parts, mining companies can enhance productivity and lessen downtime, eventually leading to a much more effective procedure.

Report this page